Standard Features

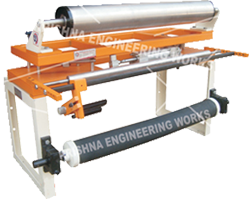

Krishna Engineering Works (KEW) specializes in manufacturing high performance Tracking Roller Assemblies (TRA) for precise web edge control and guiding applications.

Our Tracking Rollers are designed through two guide methods:

- Center Pivot Roll Guiding

- End Pivot Roll Guiding

They work in conjunction with Edge Position Control systems, consisting of TRA Rollers and SRA Frames to deliver precise film feeding and web edges alignment.

The assembly is intended to be a two rectilinear steel tubing frame operating with one frame that is stationary and the other which is movable. This is supported with nylaguide sliding blocks and a specific arc bar system for smooth travelling track of the web. The use of custom specially designed anti-slip rollers, ensure the laminate does not slide off the TRA frame and stays locked in, even at high speeds.

The Tracking Roller Assembly with Web Guiding System is suitable for Rotogravure Printing, Lamination, Flexographic Printing, Slitting, Winding & Rewinding, and other Converting Machines.

Key Benefits of Using Tracking Rollers

-

✅ Precise web edge correction for all converting machines

-

✅ Robust, heavy-duty structure designed for long-term performance

-

✅ No maintenance required due to self-lubricating linear bearings

-

✅ Versatile mounting – can be installed in any position

-

✅ Effective even on fragile materials (paper, foil, films)

-

✅ Prevents slippage and ensures smooth tracking at high speeds

The Principle of Operation in Tracking Rollers

- The TRA rotates laterally in an arc, as if around a pivot point in the plane of the incoming web path.

- The servo cylinder moves the frame, correcting and aligning the outgoing web back into position.

- Can handle delicate materials — e.g. parchment paper, thin foils, films and saturated papers — without harm.

📞 Get Custom Quote Now!

Looking for durable and accurate Tracking Rollers with Web Guiding System?

👉 Contact Krishna Engineering Works (KEW) today for tailored solutions:

📧 info@kewindia.com

📞 +91-8460728298

✅ Reduce roll defects, improve alignment accuracy, and enhance machine performance with KEW’s Tracking Roller Assemblies.

Technical Specifications

🔧 Technical Specifications of Tracking Rollers

-

Web Path Options:

-

U-shaped path (reversing web direction)

-

Z-configuration (maintaining web direction)

-

-

Mounting Flexibility: Can be mounted in any attitude, even upside down

-

Bearing Support: Solidly supported on all four corners by nylaguide bearings to eliminate deflections from cantilever stresses

-

Bearings: Radial bearings are sealed; linear bearings are self-cleaning & self-lubricating

-

Adapter Bases: Stationary floor-mounted frame/plate with nylaguide bearing support and movable frame plate

-

Servo Cylinder: Heavy-duty servo cylinder nested between frames to provide accurate guiding response to hydraulic signals

Applications

⚙️ Applications

Widely used in:

-

Rotogravure Printing Machines

-

Lamination & Extrusion Coating Machines

-

Flexographic Printing Machines

-

Slitter Rewinder Units

-

Winding & Rewinding Systems

-

Packaging & Converting Lines