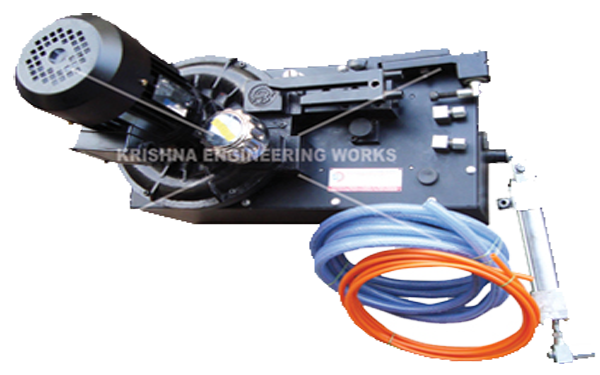

At Krishna Engineering Works, we manufacture and supply advanced Digital Edge Guide Systems designed for high-speed, high-accuracy web guiding applications. Our systems are engineered to provide precise edge alignment, reduce material wastage, and ensure perfect roll formation in rewinding, slitting, coating, printing, and lamination processes.

The Digital Edge Guide System is equipped with state-of-the-art sensors and a digital control panel to automatically detect and correct web deviation in real-time. This system is ideal for flexible packaging, paper, film, foil, textile, and other continuous web processing industries where accuracy and consistency are critical.

✅ Key Features of KEW Digital Edge Guide System

-

Digital Web Guide Controller – Advanced microprocessor-based control for fast response.

-

High-Accuracy Edge Detection – Infrared/Ultrasonic sensors for precise material guiding.

-

Real-Time Automatic Correction – Ensures wrinkle-free, uniform roll winding.

-

Compact & Robust Design – Easy to install on existing machines.

-

Low Maintenance System – Built with durable components for long service life.

-

Wide Compatibility – Works with paper, film, foil, fabric, nonwoven, and laminate rolls.

-

Energy Efficient Operation – Designed for continuous 24×7 industrial usage.

🌟 Why Choose KEW Digital Edge Guide System?

-

Over 25 years of expertise in web guiding technology

-

ISO 9001:2008 certified company

-

Export-quality machinery trusted in 45+ countries

-

Proven record in packaging, printing, textile, and converting industries

-

Strong after-sales service and spare parts support

-

Ability to custom design systems as per client requirements

Looking for a reliable Digital Edge Guide System manufacturer?

At Krishna Engineering Works, we provide custom-engineered web guiding solutions to enhance your machine performance and reduce production loss.

📞 Call Us: +91-8460728298

📧 Email: info@kewindia.com

🌍 Website: www.krishnaengineeringworks.com

Technical Specifications

⚙️ Technical Specifications of Digital Edge Guide System

-

Web Width Handling Capacity: 200 mm – 3000 mm (customizable)

-

Guiding Accuracy: ±0.5 mm to ±1 mm (depending on material type)

-

Sensors: Infrared or Ultrasonic Edge Sensors

-

Controller: Digital Microprocessor-Based Web Guide Unit

-

Actuators: Hydraulic / Pneumatic or Electric Linear Actuator (custom options)

-

Motor Drive: 0.25 HP / 0.5 HP AC Motor with Variable Speed Control

-

Operating Speed: Up to 600 meters/minute

-

Power Supply: 220V AC, 50 Hz (custom options available)

-

Optional Upgrades: Touchscreen HMI, Auto Calibration, Servo Drive Integration

(All specifications can be customized as per client’s requirements.)

Applications

🏭 Applications of Digital Edge Guide System

Our Digital Edge Guide Systems are widely used in:

-

Web Aligner For Slitter Rewinder Machines – For perfect edge alignment during roll slitting.

-

Printing Machines – Roto Gravure, Flexo, and Offset printing applications.

-

Lamination & Coating Machines – Ensures proper guiding of films, foils, and laminates.

-

Packaging Machines – For pouch making, flexible packaging, and roll winding.

-

Textile Industry – Inspection machines, batching machines, and stenter guiding.

-

Paper & Film Industry – High-speed edge guiding for paper rolls, plastic films, and foils.