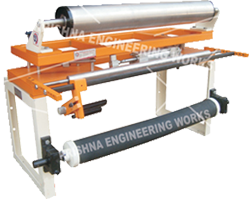

Single Roller Assembly SRA with Web Guiding System

Standard Features

The Single Roller Assembly (SRA) is a small and very effective system that is used for the positioning of materials passing through converting, extrusion, and lamination of webs with accuracy (ie. web guiding). The SRA System will give you smooth material passage while providing excellent and perfect web alignment. A proper web guide will minimize material and machine down time.

KEW’s SRA Frame with Web Guiding System consist of a precision guided roller that the web material passes through. Several distance away from the roller is a hydraulic-pneumatic adjuster that gives a motion for the frame to move automatically, correcting misalignment, and ensuring that you wind the web correctly at the rewinder station.

With over 25 years of experience Krishna Engineering Works, is the designer and manufacturer of this unit. The SRA frame has CNC machined components, imports, and other systems that include hydro-pneumatic technology, making it suitable for durability, maintenance free, and high speed applications.

Key Benefits of Using Single Roller Assembly

-

✅ Compact design suitable for multiple machine integrations

-

✅ Reduces wastage by ensuring precise edge alignment

-

✅ CNC-machined parts for high durability & long service life

-

✅ Works with various substrates: paper, film, foil, nonwoven, and fabric

-

✅ Easy installation, maintenance-free operation

Looking for a reliable and high-precision Single Roller Assembly (SRA) with Web Guiding System?

👉 Contact Krishna Engineering Works today:

📧 Email: info@kewindia.com

📞 Phone: +91-8460728298

Get your customized SRA Web Guiding System designed for your application and improve your production accuracy today!

Applications

⚙️ Applications

The Single Roller Assembly SRA with Web Guiding System is widely used in:

-

Extrusion Machines – for maintaining web alignment during film extrusion

-

Lamination Machines – ensuring smooth and accurate laminate guiding

-

Printing & Converting Lines – for high-quality printing and cutting accuracy

-

Flexible Packaging Industry – film, foil, and plastic sheet processing

-

Paper & Textile Industries – maintaining precision in unwinding and rewinding

Technical Specifications

🔧 Technical Specifications

- Electronic of the film Photocell sensor for edge.

- Electronic 0 5 HP AC Motor.

- Electrical Panel Board for Operate the complete Unit.

- Hydraulic Cylinder Adjuster Oil Pipe.

- Speed of Unit 250/min

- Variation of the film Winding is 0.5

HYDRO -PNEUMATIC Web Aligner Unit.

- 0.5 H.P. Motor

- Air Pipe 5 Mtr.

- Oil Pipe 5 Mtr.

- Sensor 1 pcs

- Adjuster 1 pcs.

- Air Filter 1 pcs.

- Oil Filter 1 pcs.

- Hydraulic Cylinder size 6 strock 1 pcs